How to Buff Clear Coat:

Safest and Simplest Tips for Beginners

Any trip onto the Internet to learn how to buff clear coat will deliver mind-bending results! Your eyes will bleed and your brain will freeze as you find yourself drowning in a sea of opinions.

Unfortunately this industry of detailing and cosmetic car care is an industry filled with massive amounts of static from so-called experts.

As a beginner you will be limited in your ability to ask the right questions when it comes to polishing clear coat on your car.

I will help you ask the questions you aren't asking:

- What is the difference between car paint and clear coat?

- What is the best car buffer to buff clear coat?

- What is the best polish to buff clear coat?

- What is the safest way to buff clear coat?

How to Buff Clear Coat:

Clear Coat vs. Car Paint

What is interesting is that you likely went looking how to buff clear coat instead of how to buff car paint. Often people ask this very basic question only after they have spent a bunch of time focused on polishing clear coat as opposed to polishing car paint.

- Is there actually a difference between clear coat and car paint?

- Is buffing clear coat different than buffing car paint?

Any original factory produced car will have what is called a 2-stage paint job that has been finished with clear coat. The color coat (which most people think of as the paint) will sit below the clear coat.

If you really want to take a deep dive into all things clear coat, I suggest you read my page at what is clear coat.

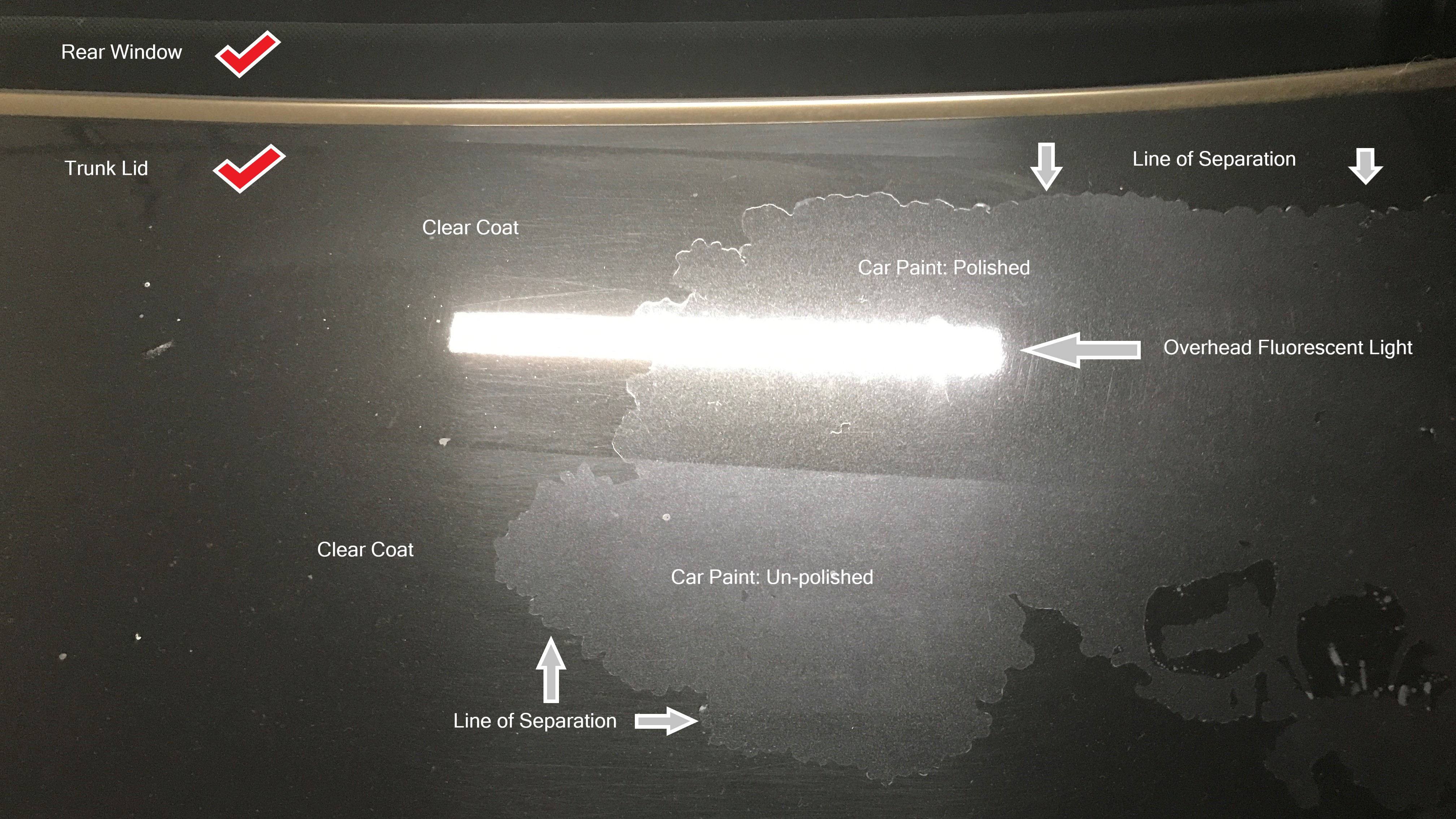

Here is a shot taken of a 1999 Mercedes C280 showing clear coat failure to highlight the difference in layers between clear coat as the top coat, and car paint beneath

Here is a shot taken of a 1999 Mercedes C280 showing clear coat failure to highlight the difference in layers between clear coat as the top coat, and car paint beneathThis page is written based on the understanding that your car will have clear coat as the top layer as part of the original factory paint system.

Car paint and clear coat are the same thing....mostly.

There is a definite distinction between them as to the specific roles they serve as part of the overall paint system, but the key point is to know that regardless of your situation, any lesson on how to buff clear coat would be exactly the same lesson on how to buff car paint.

The major difference between car paint and clear are as follows:

- Car paint creates the color

- Clear coat adds a layer of protection (UV and infrared light from the sun, along with protection in general)

- Clear coat creates the high gloss and depth to the color coat of paint below

What is the Best Buffer to Buff Clear Coat

The best buffer for a beginner is a dual-action, random orbital car buffer. This applies to all types of paint and clear coats, whether soft or hard. (Every car manufacturer uses its own clear coat formula, which can vary between brands.)

As a beginner, your priority should be safety and simplicity when learning how to buff clear coat.

A random-orbital DA (dual action) is the safest and simplest way to produce professional results when polishing clear coat.

These random-orbital, dual-action buffers spin as well as "vibrate". The reason these type of buffers are the preferred choice with most people are the following:

- Super easy learning curve:

The truth is that these buffers really have no learning curve. These machine polishers are so easy you simply turn on and start buffing. The hardest part in buffing clear coat is more about figuring out what polish to use, what pads to use, how long you need to polish each section, etc.

- Dual-action design

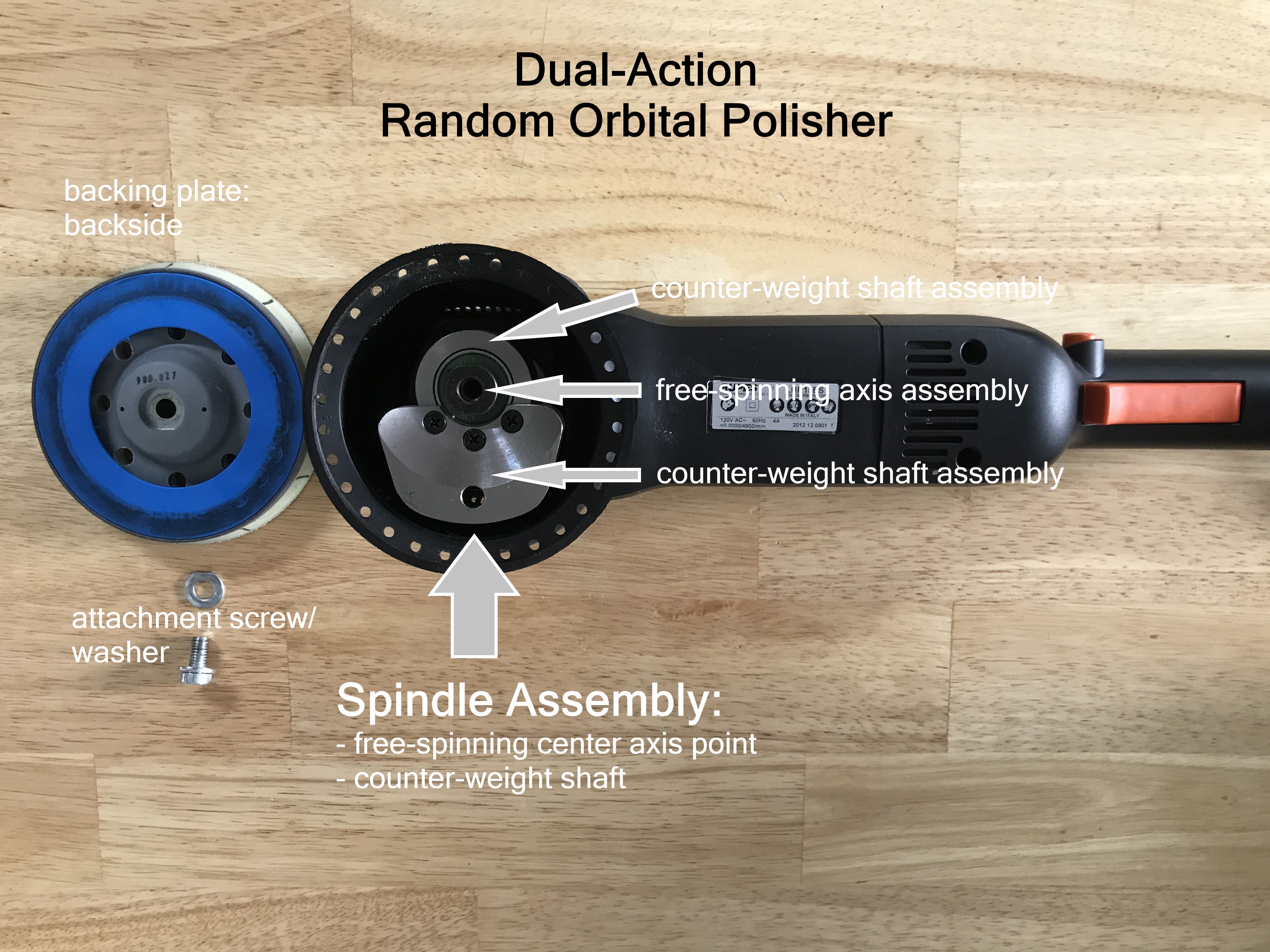

The full description of these preferred buffers of choice by both beginners and professionals are dual-action, random-orbital car buffers. These machine polishers have two movements of the polishing head compared to the single spinning movement of a rotary polisher.

Dual-action (DA) refers to the fact that the polishing head has two movements: spinning and rotating. The concept is to mimic that of your arm and hand as you would normally apply wax or polish (think "Karate Kid" and wax on, and wax off)

The random-orbital refers to the free-spinning action of the center axis assembly. Since this spinning movement is not gear driven, but works off of the inertia of the main spindle, the spinning movement will cease when too much pressure is applied.

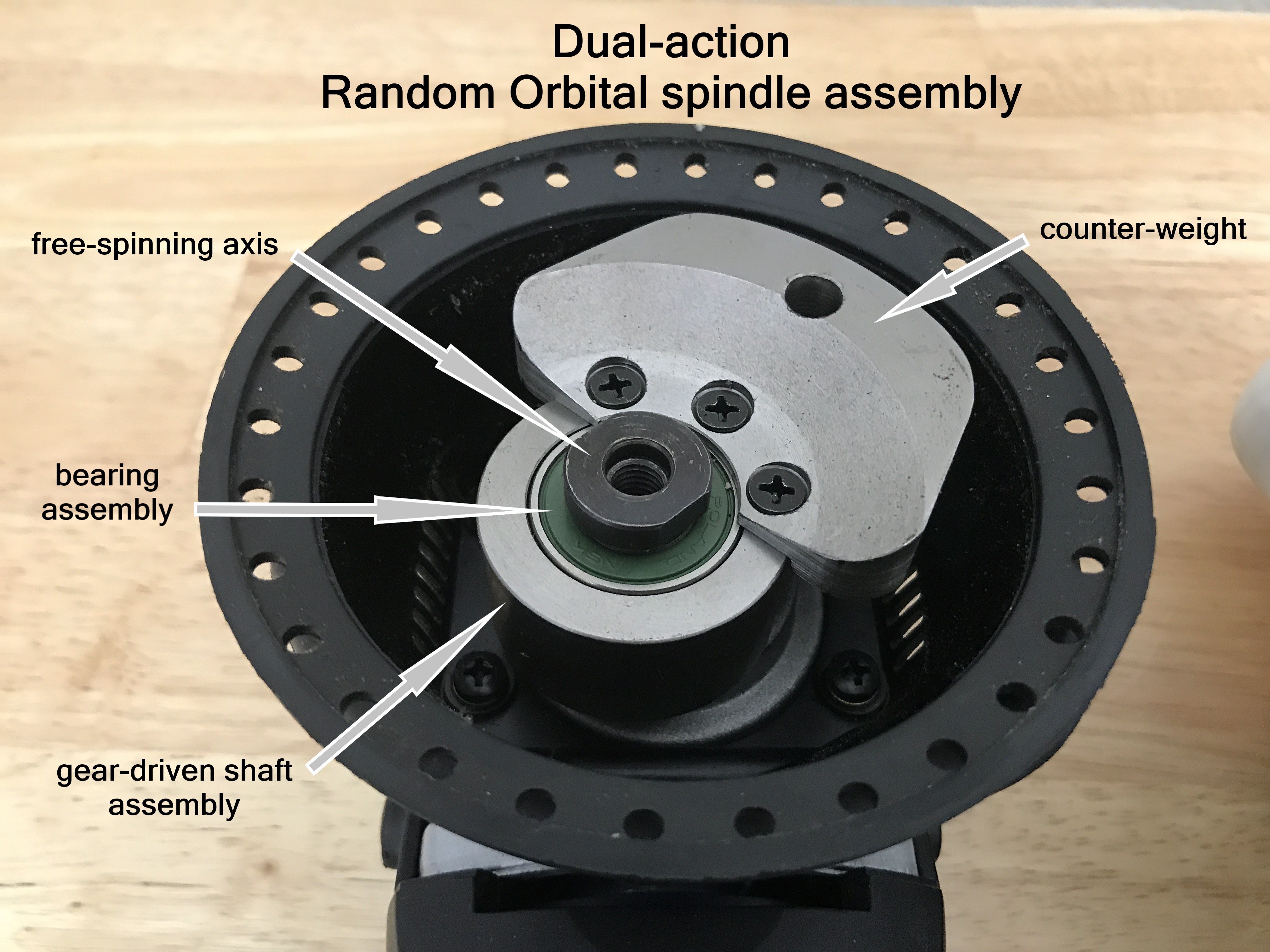

- Main spindle assembly:

The main spindle assembly is gear-driven and rotates in a small circular pattern. The free-spinning axis assembly sits in the center of the main assembly but is free-spinning.

That is a long description in describing why exactly these types of random orbital buffers are so safe when compared to the gear driven rotary polisher that countless buffer horror stories are attached to.

Free-spinning Axis Assembly: This is the free-spinning point of attachment. The center of this spindle is threaded and is the point of attachment for the backing plate. This free-spinning assembly is what gives the polishing head the spinning rotation movement of the polishing pad. Since it is not gear driven, it only spins as a natural byproduct of the movement of the off-set, counter-weighted shaft assembly during operation.

Counter-weight Shaft Assembly: This is the "gear driven" part of the assembly. The entire spindle assembly rotates in a circular shape. Imagine a small circle pattern that the entire spindle assembly moves in. This counter-weighted shaft assembly moves in a small circular rotation based on the buffer type: 15 mm vs. 21 mm (this is also referred to as short throw vs. long throw respectively) Since the overall spindle assembly is off-set, a counter-weight is attached to the opposing side to allow smooth operation.

If you are familiar with how crank shafts of combustion engines are designed, you can use that as a comparison. off-set and then counter-weighted for smoother operation

Bearing Assembly: The green bearing assembly from the picture above is what allows the center axis to spin freely within the larger spindle assembly that is an off-set spindle assembly.

Gear-Driven Shaft Assembly: This is the entire gear-driven shaft assembly that is off-set so that the polishing head moves in a small circular pattern. This main gear-driven shaft assembly always remains in movement when polisher is turned on, as opposed to the free-spinning center axis assembly. Since the center axis is free-spinning, when too much pressure is applied to polishing head, the spinning of the pad stops, but the overall spindle shaft continues to rotate in a small circular pattern.

Between this description and the included pictures you are hopefully beginning to understand just how a dual-action, random orbital car polisher works. It

is an explanation far easier to understand when seeing the mechanisms

in action rather that attempting to explain through written word and pictures.

Unlike a rotary polisher that is gear-driven and spins on a single axis point, the combination of the two movements of the dual-action polishers make these machines easier to learn and safer to use if you are a beginner.

Rotary polishers however, will out perform any dual-action polisher when it comes to their efficiency in performing heavy duty polishing requirements.

The unique design of this free-floating, counter weight design makes the random-orbital the best buffer of choice when learning how to buff clear coat.

How to Buff Clear Coat:

Safer and simpler

Now that you have a better understanding of how the recommended buffers work to buff the clear coat on your car, let's look as some kits that you can use to get professional level results even as a complete beginner.

Adam's Car Polishing Kit on Amazon

- Powerful & Efficient – 1000W motor delivers more power and torque for faster, easier paint correction. Removes swirls, scratches, and debris for a flawless finish.

- Ergonomic & Balanced – Vibration-absorbing rubber contact points enhance control and comfort. Features a balance block for easy storage and a soft-touch head cover for convenience.

- Multi-Purpose Use – Ideal for polishing, carpet scrubbing, and applying glazes, sealants, and wax. Works on chrome, aluminum, and diamond plate metals. Weighs under 5.5 lbs with a 16-ft cord.

- Strong Correction Power – 9mm orbit with 1000W and 6500 OPM ensures even polish distribution and full vehicle paint correction. Built for long-term performance.

- Satisfaction Guaranteed – Backed by Adam’s 110% guarantee. If you're not satisfied, we’ll make it right.

Chemical Guys Car Polishing Kit on Amazon

- Fast & Precise Paint Correction – Achieve flawless results with the lightweight, agile TORQ R Rotary Polisher, designed for comfort and control during long polishing sessions.

- Digital RPM Control – Adjust the powerful 900W motor with a digital interface, featuring 7 speed settings for precise performance.

- Ergonomic & User-Friendly – Enjoy comfortable polishing with an intuitive design and easy-to-use spindle lock for quick backing plate changes.

- Versatile Polishing Compounds – The V-Line Polish System includes 4 compounds to remove scratches, imperfections, and enhance shine.

- Premium Polishing Pads – Three Hex-Logic pads (cutting, polishing, finishing) ensure the perfect finish for any paint correction job.

Clear Coat Thickness and Your Paint

One thing very few people talk about when learning how to buff clear coat is clear coat thickness.

Clear coat thickness is a big part of the UV protection offered with clear coat on your car. This means that as you polish your car to restore shine and remove paint defects, you will also be thinning-out your clear coat.

The thinner your clear coat is, the less UV protection offered from the clear coat itself.

If this really is true (it is!), then as a car owner you would want to do your best to create better shine and less defects, while retaining as much of the original clear coat thickness as possible.

I am not teaching you this to alarm you away from polishing your paint, I say this to help you be as informed as possible.

As you can see in the picture below, any "thicvkness" you remove as a byproduct of polishing is very much worth it!

The reality is that unless you were trying to do damage to your paint, the amount of thickness loss as a result of buffing the clear coat is negligible.

This picture shows the dramatic results possible when using a dual-action machine polisher to buff the clear coat on this original, 1999 Mercedes.

This picture shows the dramatic results possible when using a dual-action machine polisher to buff the clear coat on this original, 1999 Mercedes.Clear Coat Buffing Instructions:

- Wash/Dry car

- Decontaminate clear coat/paint surface with detailing clay

- Assemble your buffer, buffing pad, and car polish

- Decide how you will section car off with regards to polishing section to section of entire car (will you start with hood and break that down into smaller sections, or start with sides of car?)

- It is best to polish out of direct sunlight

- Set your buffer to level 5 (most car polishers will have a speed setting of 1-6)

- Apply 10 pea size drops of car polish onto face of polishing pad

- Set buffer pad directly onto paint surface and turn on while maintaining control of buffer

- Slowly move buffer in a grid pattern within a section of 2x2 feet of paint surface area (you can move buffer slowly from left to right, then back and forth within entire 2x2 foot area)

- Remove buffer from paint surface

- Use micro-fiber cloth to remove polish residue and check results

- Inspect area you have polished for results: if you are not satisfied with results, then apply about half as much polish as the first time, and repeat polishing

Darren's Tips: You will never be able to learn "experience". This is me telling you that regardless of how well I can describe every conceivable step in learning how to buff clear coat, it will never replace the hands-on experience you will have to get yourself by doing.

Don't overthink things at the beginning. I have laid out all the exact steps I teach guys firsthand on the safest way in learning how to buff clear coat within this page.

How to Buff Clear Coat Summary

If you have made it this far in your quest to learn how to buff clear coat then you are now part of a very small group of car owners dedicated to the health and beauty of your car's clear coat.

The learning process can be agonizing at times, but the rewards are great if you stick with it and filter through the endless opinions on the subject.

Just remember that you cannot learn everything at once! Be patient with yourself and accept that every bit you learn, goes into your tool box of knowledge that you can continue to develop at your own pace.

My goal is to always simplify the process and help you make informed choices.

Sincerely,

Darren Priest

- Home

- Car Clear Coat

|

|